NJ501-5300

NJ-series NC Integrated Controller

Realize high-accuracy synchronization motion control (MC) and numerical control (NC) functions by ONE controller.

last update: February 14, 2022

Three benefits from NC Integrated Controller

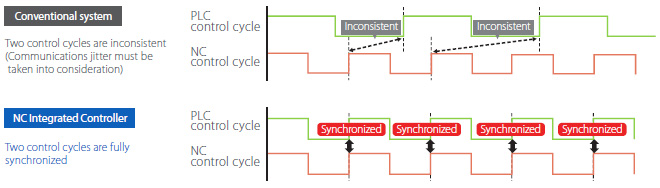

[Minimize machine cycle time] NC and PLC functionality fully synchronized at high speed

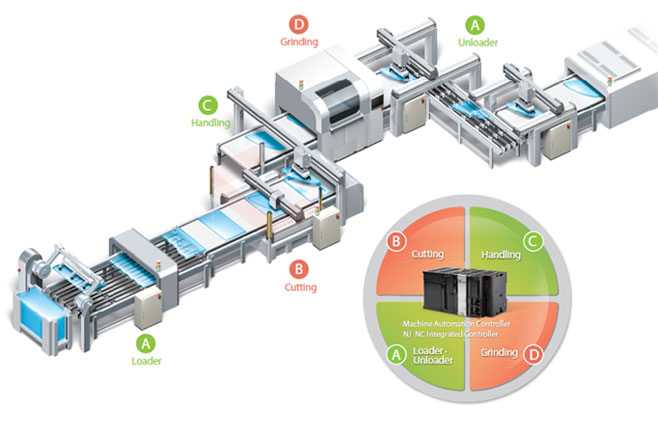

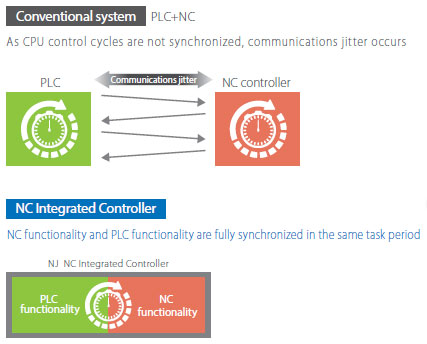

Efficient control of processing and other processes is crucial to performance and productivity of a multi-purpose machine which handles multiple processes.

The NC integrated controller provides both NC and PLC functionality and synchronize all devices at high speed, significantly reducing the machine cycle time.

Improved synchronization

Control cycle as you designed

Programs for both PLC and NC are executed in the same task period, which enables processes to be synchronized with the cycle as you designed

High-speed synchronization reduces interlock time

Interlock time between NC (processing) and PLC (other processes) will be reduced to 1/4 as compared to when separate controllers are used. Cycle time of a multi-purpose machine that generates many interlocks can be reduced.

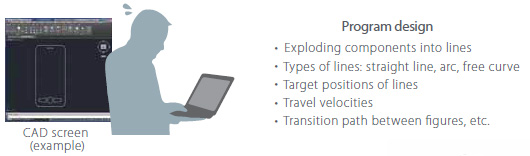

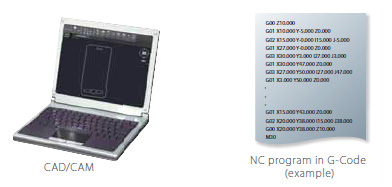

[Simplify complex profiling] Versatile NC functions

G-Code reduces time required to design and program complex profiling.

Conventional controller

Processing programs are designed based on CAD data. Programming using PLC instructions and debugging are required for each figure

NC Integrated Controller

CAD/CAM software makes design easy

Parameter setting

(1) Parameters are set using CAD/CAM software

Automatic generation

(2) NC program in G-Code is generated

Transferred

(3) Program is transferred to NC integrated controller

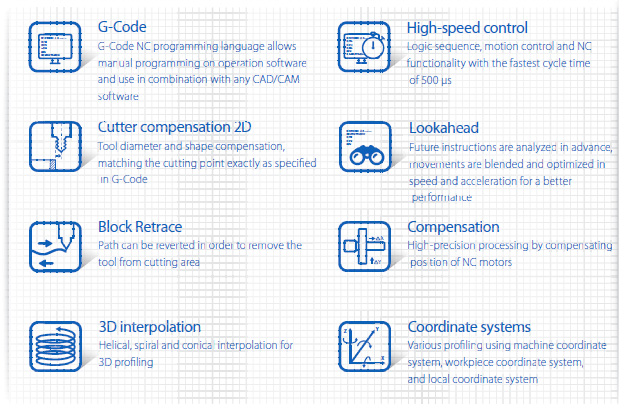

NC functions for complex profiling applications

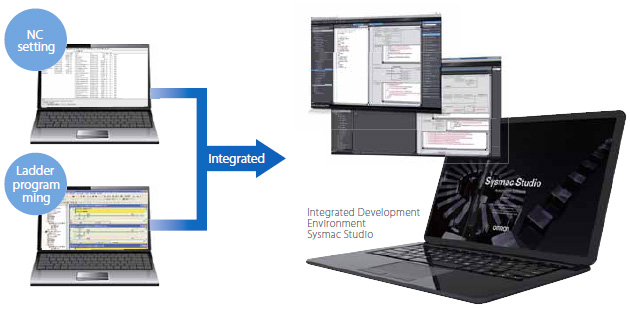

[Optimize engineering time] One software for NC setting and PLC programming

The Sysmac Studio provides a true Integrated Development Environment (IDE) for configuration, programming, monitoring, and 3D simulations. Programming based on IEC standard and PLCopen® Function Blocks (FBs) for motion control cuts programming time. FBs for NC control make program structure simple, even for synchronization between NC process and others.

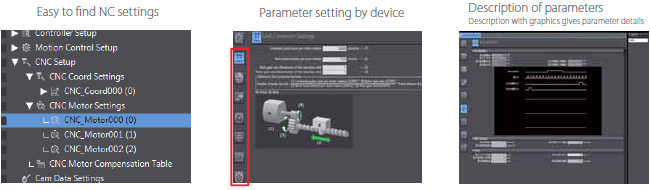

Intuitive user interface reduces configuration time

last update: February 14, 2022