NB Series

Programmable Terminals

Quality color display with LED backlighting. Complete HMI family. Comprehensive features.

* Information in this page is a reference that you created on the basis of information in the product catalog before the end of production, may be different from the current situation, such as goods for / supported standards options / price / features of the product. Before using, please check the compatibility and safety system.

last update: June 8, 2020

The future-proof, compact HMI

Give more value to your machines with Omron’s NB Series: compact range application HMI.

Enjoy his the aesthetic sense and excellent visibility.

Our expertise in Factory automation give you warranty of quality and a total freedom to build up optimal applications.

Newly added remote control features help to reduce the time and work involved in maintenance.

Enjoyable to use

The newly added remote control features significantly save you time, and the flexible design features make screen creation easier.

All these features greatly contribute to your global scale business.

Global support from local site

Flexible remote access function

Besides conventional web browsers, now NB Series supports faster and secure Virtual network computing (VNC), providing exible remote access.

Powerful remote operation

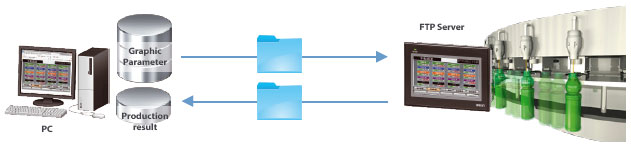

With the newly added features such as FTP Server and CSV data-copying features, you can change machine parameters from remote locations or host PC, and collect production data.

Now graphics can be updated even during the operation, and visual can be changed without stopping the HMI following changes in machines and recipes.

Easily create intuitive operator screens

Flexible window handling

NB Series easily creates screens for your project.

Besides the standard window, you can also create ‘window-in window’. Furthermore, it also supports bottom windows and transparency for pop-up windows.

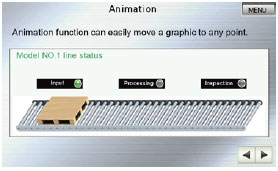

Easy animation

Animations can be created easily. For example, you can show a different status with text and graphics, or move the components while changing them. This easy animation feature makes the operation easier to understand and eliminates the need for expertise.

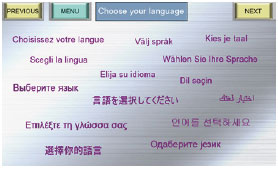

Extensive language support

Thanks to the supported 32 languages and Text Library function, you will find it easy to manage texts in multi-language.

This allows users to operate the HMI in the language they choose.

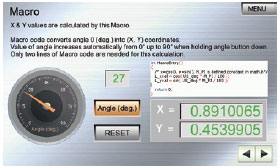

Powerful macros

Thanks to its powerful macros, you can perform calculations and comparisons or iterations, and mathematical functions.

It also enables you to do even more.

Pleasant to program

Ready to use functions for your machine

The feature-rich NB series has everything you will need for creating applications for a wide range machines and in many industries, for example, packaging, food, plastics and textiles. From a simple lid placing or loading/unloading machine right up to an in-line filling or sealing /labeling packaging machine. Download free of charge NB-Designer software from Omron web site.

Always informed about alarms

Event monitoring (alarming) is both flexible and easy to use. Not only do you have the possibility to enter bit and word alarms for on/off or on-condition triggering, there is also the possibility to use different fonts and color to indicate varying degrees of status and priorities. Specific alarms are indicated with an audible buzzer sound, as well as by an accompanying text message, and you can even create pop-up alarms for situations where immediate action has to be taken.

Easy data presentation

Graphical representation of real-time and historical data is easy with the NB series. As well as display of time sampling and trending data, you have the option to save sampling data (max. 16 consecutive words) of basic real-time trending data. And you can plot using x/y coordinates, in which case sampling can be done via single or multiple points and with historical data. Furthermore, data can be presented in a variety of ways, such as sampling points using x and y components.

Multiple security options

Protecting your developed project with a password using the NB series is both a simple and secure matter. Among the comprehensive security options is the possibility to define up to 16 minimum security levels on screens, buttons and inputs, and you can set up to 32 specific permission controls for each operator. There is also a register condition (bit/word) control for a check of actual condition against a predefined value, and a standard operator confirmation check to confirm that critical actions have been performed by the operator.

The perfect partner for Omron devices

Omron Compact controllers perfectly match your specific automation requirement and connection to the NB series is possible via Serial or Ethernet.

Ethernet protocols, FTP or VNC make easy remote access for maintenance or data gathering and allows digitalisation of your machine.

last update: June 8, 2020

Product Category

Product Category

Automation Systems

Automation Systems

-

Programmable Terminals

Programmable Terminals

-

Discontinued

- NB Series

-

Discontinued

-