V400-F

2D Code Reader

Created to meet real-world production site needs.

* Information in this page is a reference that you created on the basis of information in the product catalog before the end of production, may be different from the current situation, such as goods for / supported standards options / price / features of the product. Before using, please check the compatibility and safety system.

last update: December 19, 2013

Simplified Setup...

For Faster Startups

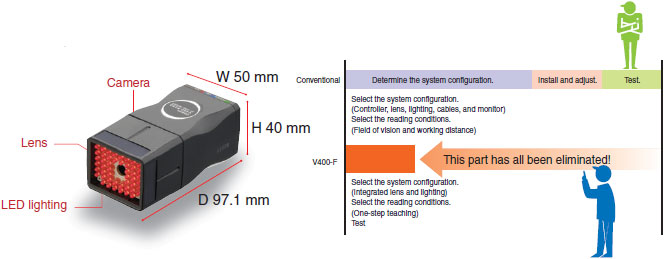

Simpler Selection with a One-piece Design

The selection process is greatly simplified by the integrated lens and lighting design.

No more worrying about having to match each workpiece to a vast number of lens and lighting combinations.

Easier Initial Adjustments

Teaching functions that anybody can use.

Naturally, adjustments are also possible using commands from external devices.

* Support Software is also available for setting the parameters from a personal computer.

(Ask your OMRON representative or dealer for details.)

Banks...

Dramatically Reduce Process Changeover Steps

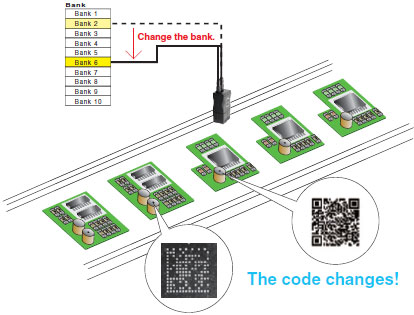

Change the Process without Stopping the Line

The Auto Bank Change function lets the operator automatically change preset reading conditions recorded in banks. Up to five banks can be set in advance to greatly reduce bothersome steps when changing the line process.

High Performance...

For Stable Reading

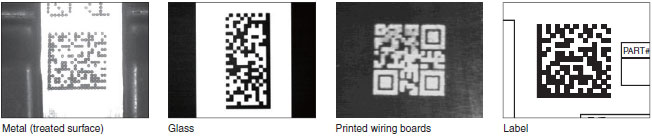

Stable, Accurate Reading for Any Workpiece

We have achieved high accuracy for directly marked codes by combining the industry's most advanced reading algorithm with lighting control that is optimized for data reading. Even directly marked 2D codes printed onto materials with varying reflectivity, such as metals, printed wiring boards, and glass, can be read with excellent accuracy.

Three Types to Choose from for Each Application

There are three 2D Code Readers to choose from to match your application. This enables flexible response to different workpieces and production site conditions. Use the C-mount model when specific settings are necessary for the lighting or lens.

Sensitive Response to Workpiece Changes

The Retry and Preprocess Filtering functions allow stable reading even under harsh conditions. They eliminate the effects of printing conditions and workpiece changes, such as oil, ambient light, and varying substrate types.

Retry Function

Multiple readings can be taken while changing the exposure time and adjusting the brightness of the light.

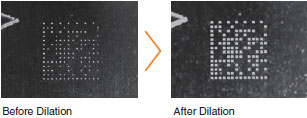

Preprocess Filtering Function

Three of the following four types of filtering can be used for images that have been taken: Smoothing, Dilation, Erosion, and Median.

last update: December 19, 2013

Product Category

Product Category

Sensors

Sensors

-

Code Readers / OCR

Code Readers / OCR

-

Discontinued

- V400-F

-

Discontinued

-