STC-FDR

Factory Drive Recorder

Record the moment of an event

last update: November 1, 2023

Efficient identification of problem causes with a video recorder

Simple configuration facilitates installation

Breakage of objects at an unmanned factory operated by robots

Grasp unexpected behavior of robot arms

If products are scratched at an unmanned site, it takes time to identify the cause because it is impossible to know what happened.

Recording robot behavior on each command enables you to understand the situation when a problem occurs and to quickly analyze the cause.

・ Recording trigger: Production command signal from PLC

・ Recording on a production lot basis

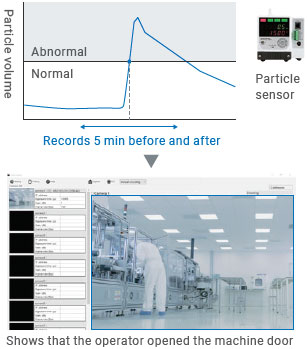

Quality defects at a production site where the environment is strictly controlled

Grasp that the operator is working with the sterile machine door opened

When a defect occurs at a production site where sterile machines are used, it is difficult to identify the cause because the situation is unknown.

For example, the camera records a video showing the machine state before and after the particle volume abnormality, leading to identification of defect causes.

・ Recording trigger: Sensor installed for environmental measurement

・ Automatic recording before and after abnormality

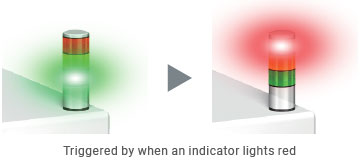

Record the moment of state change

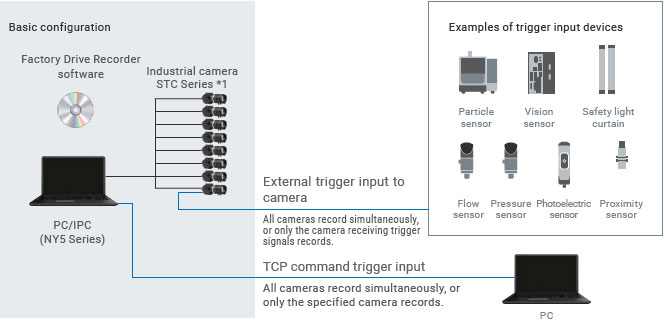

Automatic recording of events by trigger input

The camera records a video showing the machine state for up to 60 minutes before and after the problem by being triggered by external input from the sensor or PLC or by TCP command input. This allows you to quickly understand what happened by replaying the video.

[Case] Recording triggered by particle volume abnormality

[Case] Recording of work process triggered by inspection fail

Factory-specific recording functions for various applications

This software provides seven types of recording: Trigger Recording that includes Time Trigger, Motion Detection, and Master Image Comparison as well as external trigger input, Continuous Recording that records a video for up to one year, and Manual Recording for 60 minutes. It can be used for continuous remote monitoring of machine status, review of production problems, work process tracing for recall purposes, and many other industrial applications.

Automatic recording by detecting change in image

Videos before and after problems can be recoded by Motion Detection that uses the difference from the preceding image under specified conditions (see below), and Master Image Comparison.

Remote status monitoring + continuous recording

You can remotely monitor the site status in real time without recording or continuously record for up to one year*1.

*1. Recording time varies depending on the storage capacity of your PC or HDD.

Accurate recording of events with various types of cameras

Omron offers a wide selection of more than 100 models of cameras to meet your needs.

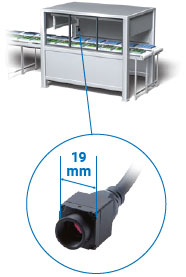

Fits in narrow spaces

The 19 mm square ultra-compact remote head camera can be installed in narrow spaces.

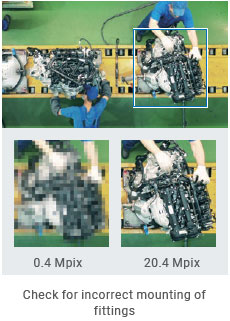

Records subtle changes

The 20.4 Mpix high-resolution camera can clearly record changes in machine state.

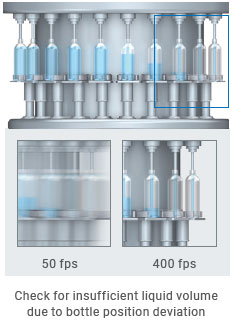

Records high-speed lines

A 0.4 Mpix camera can record high-speed production lines as fast as 400 fps.

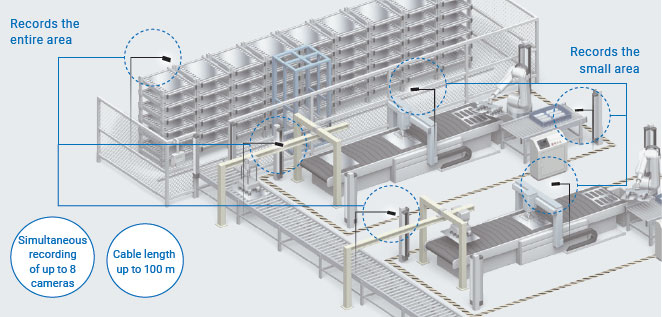

Simultaneous recording of wide and narrow areas

Omron’s broad portfolio of cameras, including a camera with a long cable required for wide-area recording to shoot the entire manufacturing site, can be freely combined with lenses for different fields of view. These combinations enable capturing wide and narrow areas at the same time, allowing you to accurately analyze problems by replaying the videos.

3-step easy system configuration

[STEP1] Prepare devices

The camera and software bundle is ready for immediate use without the need for verification and programming which are required to build a system by combining general cameras with vision software. Recording can be started immediately by using input from the sensor or PLC installed at the production site as trigger.

specifications and the number of connected cameras.

*1. Omron's STC Industrial Cameras can be used. See Lineup for details.

[STEP2] Install

I nst a l l the Fa c to r y D r i ve Rec o rder s o f tware a nd camera driver (SentechSDK)*1 on your PC or IPC.

*1. Install the latest version of the camera driver (SentechSDK) downloaded from the Omron Sentech’ s website.

[STEP3] Set recording conditions

Configure camera settings, recording settings, and settings for saving recorded videos.

· Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

· Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

· The product photographs and figures that are used in may vary somewhat from the actual products.

· GigE Vision and USB3 Vision are trademarks of AIA (Automated Imaging Association).

· Images used under license from Shutterstock.com.

· Other company names and product names in this document are the trademarks or registered

trademarks of their respective companies.

last update: November 1, 2023