Enhancing safety through two-tiered monitoring for temperature anomalies in the manufacturing process

lastupdate: 2023/06/30

Preparatory processes for semiconductor/FPD manufacturing involve several high-temperature procedures. Failure to sufficiently control temperatures during these procedures can lead to serious incidents, but adding equipment to improve safety would increase the facility's footprint.

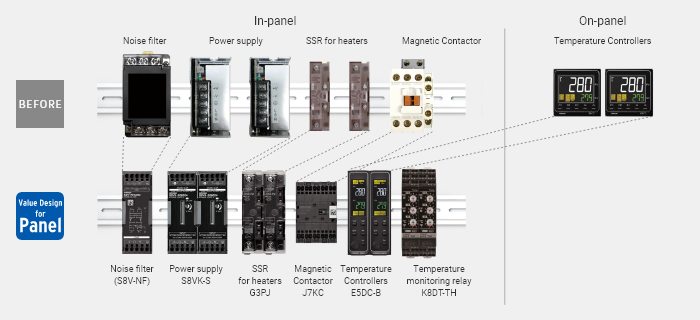

Improving facility safety without increasing footprint

Omron’s Value Design for Panel products consume dramatically less space compared to their previous counterparts. In the case of temperature control devices, for example, measures such as side-by-side mounting of power supplies and heater SSRs allow all equipment to fit inside the panel, and even make room for temperature monitoring relays that ensure facility safety, as shown in the figure below.

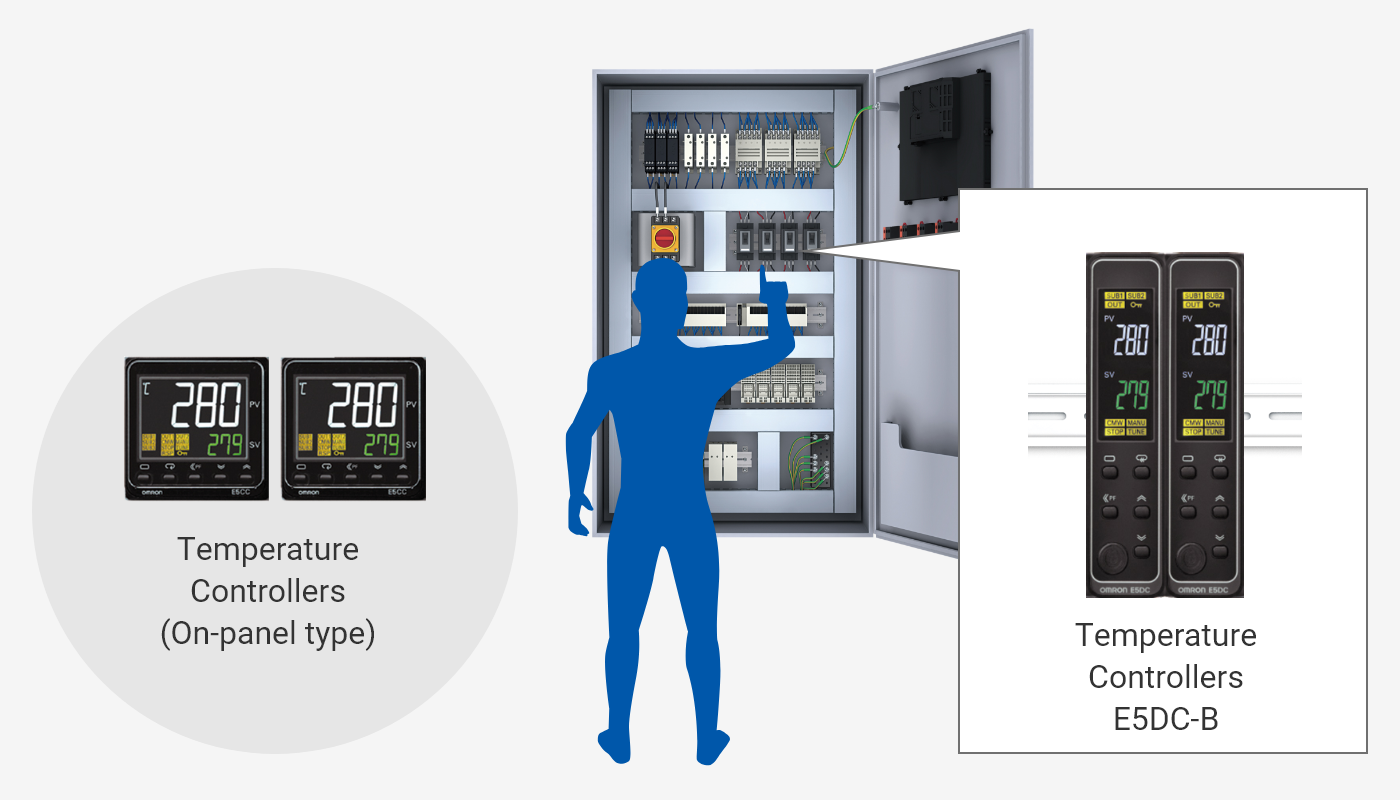

Same operability with less wiring

Same operability as on-panel models Compact 22.5 mm-wide DIN track-mounting model with operabilitycommon to E5 □ C Temperature Controllers saves panel space.

Horizontal connection structure reduces crossover wiring effort